The Evolution and Benefits of High-Speed Saw Machines

At the heart of high-speed saw machines is their ability to operate at rapid speeds, often exceeding 1,500 RPM. This high-speed operation significantly reduces cutting time, allowing manufacturers to increase productivity and meet growing demands. Traditional saws, while effective, often fall short in terms of speed and efficiency. High-speed saw machines, on the other hand, utilize powerful motors and advanced blade technology, resulting in cleaner cuts and reduced material waste. This efficiency not only saves time but also lowers operational costs, making them an attractive option for businesses aiming to optimize their production processes.

One of the most notable advantages of high-speed saw machines is their versatility. These machines can be used to cut a variety of materials, including wood, metal, plastic, and composites. This adaptability makes them ideal for industries ranging from construction to automotive manufacturing. The ability to switch between materials without compromising quality is a significant benefit that enhances workflow and reduces the need for multiple machines.

Moreover, the design of high-speed saw machines often incorporates features that enhance safety and ease of use. Many models come equipped with advanced safety guards, automatic shut-off mechanisms, and user-friendly interfaces that reduce the risk of accidents. These safety features not only protect operators but also contribute to a smoother operational flow, as workers can focus on their tasks with peace of mind.

Innovation in blade technology has also played a crucial role in the advancement of high-speed saw machines. Blades made from high-quality materials such as carbide or diamond-tipped options offer improved durability and cutting performance. These blades are engineered to withstand the high speeds and pressures associated with rapid cutting, resulting in longer lifespan and reduced frequency of replacements. The combination of high-speed operation and superior blade technology ensures that manufacturers can achieve consistent results without the need for frequent maintenance.

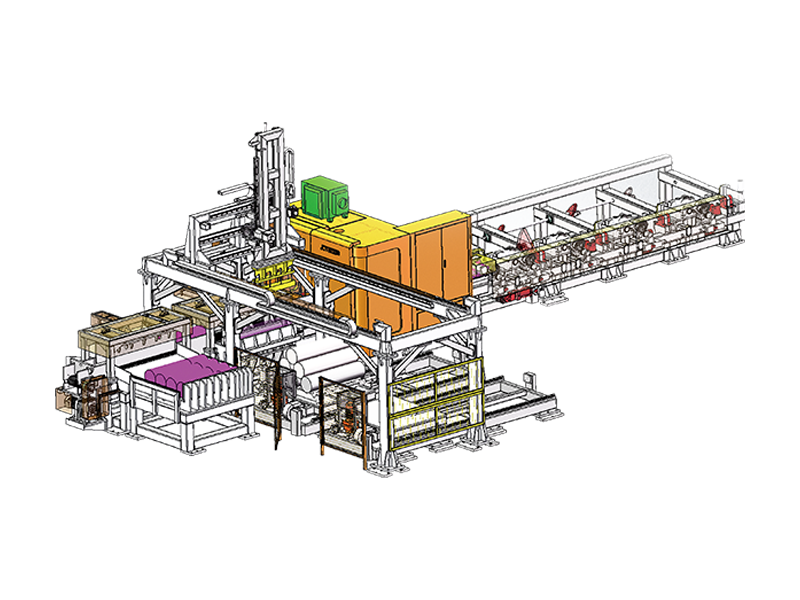

In addition to performance enhancements, high-speed saw machines are increasingly being integrated with automation and digital technologies. The incorporation of CNC (Computer Numerical Control) systems allows for precise cutting patterns and automated adjustments based on material type and thickness. This technological integration not only boosts productivity but also enhances the quality of the finished product, as the machines can execute complex cuts with minimal human intervention.

中文简体

中文简体 русский

русский