How does the development of high-speed pipe saw technology reflect broader trends in industrial automation?

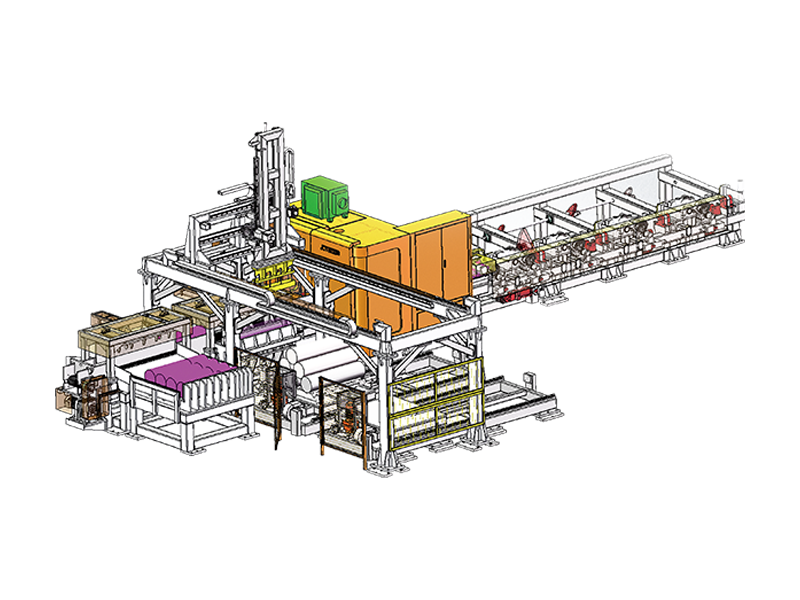

The development of high-speed pipe saw technology, exemplified by innovations like the GK series High Speed Pipe Saw Machine Tool from JWT Company, mirrors significant trends in industrial automation that are reshaping modern manufacturing landscapes.

Firstly, high-speed pipe saw technology embodies the trend towards enhanced efficiency and productivity. By utilizing advanced cutting mechanisms and optimized processes, these machines can significantly reduce cycle times and increase throughput compared to traditional methods. This efficiency not only improves the bottom line for manufacturers by lowering production costs but also allows for quicker response times to market demands.

Secondly, the integration of sophisticated control systems and software in high-speed pipe saw machines reflects the broader shift towards smarter, more interconnected industrial systems. These machines often feature programmable logic controllers (PLCs) and computer numerical control (CNC) capabilities, enabling precise control over cutting parameters and seamless integration into automated production lines. Such automation not only improves accuracy and consistency but also enables real-time monitoring and adjustment, thereby enhancing overall operational efficiency.

Furthermore, high-speed pipe saw technology aligns with the growing emphasis on sustainability and resource efficiency in manufacturing. The narrow saw kerf and optimized blade usage characteristic of these machines minimize material waste, contributing to greener production practices. This focus on sustainability is increasingly crucial as industries seek to reduce their environmental footprint while maintaining high production standards.

Moreover, the development of high-speed pipe saw technology reflects a broader trend towards customization and flexibility in manufacturing. These machines can be configured to handle a variety of materials, sizes, and cutting requirements, offering manufacturers the agility to adapt quickly to diverse production demands. This flexibility is essential in today's competitive markets where rapid customization and shorter product lifecycles are becoming the norm.

Additionally, the evolution of High Speed Pipe Saw Machine Tool technology underscores the importance of operator safety and ergonomics. Modern machines are equipped with advanced safety features and ergonomic designs to protect workers and enhance their comfort during operation. This commitment to safety not only ensures regulatory compliance but also boosts morale and productivity among manufacturing teams.

In conclusion, the development of high-speed pipe saw technology not only represents advancements in cutting-edge machinery but also reflects broader trends towards efficiency, automation, sustainability, flexibility, and safety in industrial automation. As manufacturers continue to embrace these technologies, they are poised to unlock new levels of productivity and competitiveness in a rapidly evolving global market.

中文简体

中文简体 русский

русский