How Circular Saw Machines Are Revolutionizing the Manufacturing Industry

The Role of Circular Saw Machines in Modern Manufacturing

Circular saw machines are a cornerstone of modern manufacturing operations. Whether used for cutting wood, metal, or plastic, these machines offer precise and efficient solutions for businesses looking to optimize their production lines. Their versatility makes them suitable for a wide range of applications, including furniture manufacturing, construction, automotive production, and metal fabrication.

One of the key advantages of circular saws is their ability to make clean, straight cuts with minimal effort. This precision is particularly important in industries where small variations can result in costly defects or delays. Whether it's cutting large sheets of metal in automotive production or trimming wood to size for furniture, circular saws ensure that the final product meets exact specifications.

Increased Efficiency and Speed

In the fast-paced world of manufacturing, time is money. Circular saw machines have helped companies drastically reduce cutting times, enabling them to complete more tasks in a shorter amount of time. Automated circular saw machines, for instance, are capable of running continuously without the need for human intervention, further increasing operational efficiency.

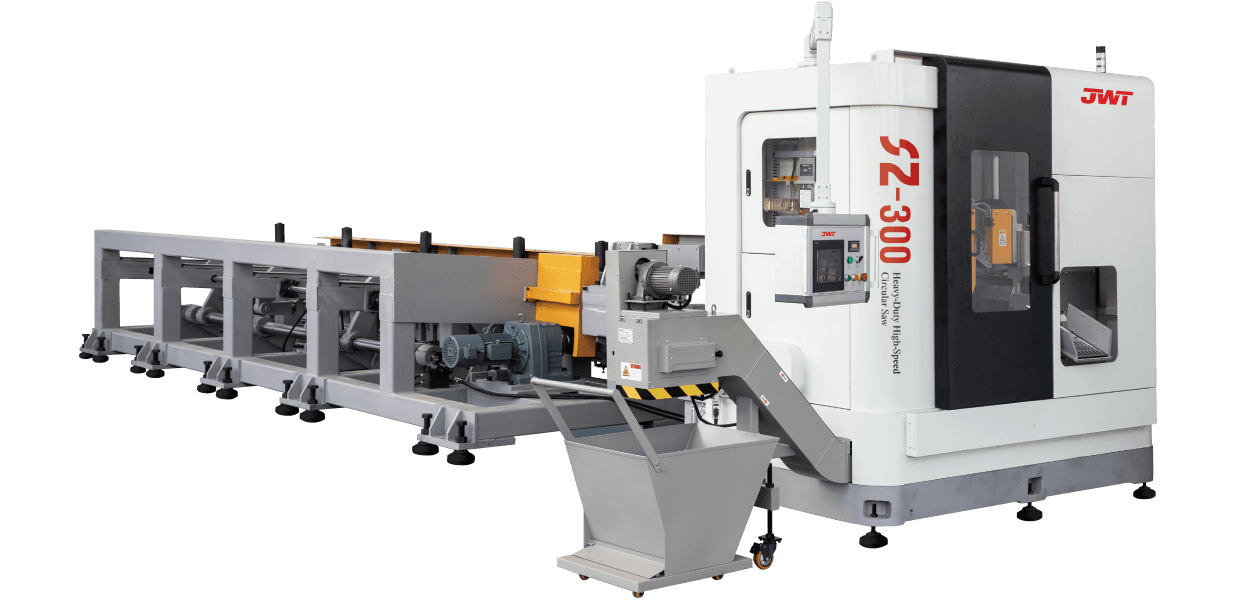

Some models of circular saws are equipped with high-speed motors and sophisticated cooling systems, allowing them to cut through tough materials like stainless steel or thick hardwoods with ease. This enhanced cutting power helps manufacturers meet tight deadlines and stay competitive in an increasingly globalized marketplace.

Improved Safety Features

Safety is always a top priority in manufacturing environments, and modern circular saw machines come equipped with advanced safety features to protect operators. Features such as blade guards, emergency shut-off switches, and automatic braking mechanisms help minimize the risk of accidents. These safety features are especially important in industries where high-speed cutting operations are commonplace.

In addition to traditional safety measures, many circular saw machines are designed with user-friendly interfaces that provide operators with clear instructions and warnings. For example, many machines include safety interlocks that prevent the saw from operating unless it is properly set up or calibrated, reducing the chances of user error.

Customization for Specific Applications

Another advantage of circular saw machines in the manufacturing industry is their ability to be customized for specific applications. Depending on the material being cut and the desired end result, manufacturers can select circular saws with different blade sizes, cutting angles, and motor capacities. For instance, a company specializing in the production of precision metal parts may choose a high-performance circular saw designed specifically for cutting metal alloys with tight tolerances.

中文简体

中文简体 русский

русский