How Automatic Saw Machines Revolutionize Industrial Cutting Processes

What Sets Automatic Saw Machines Apart?

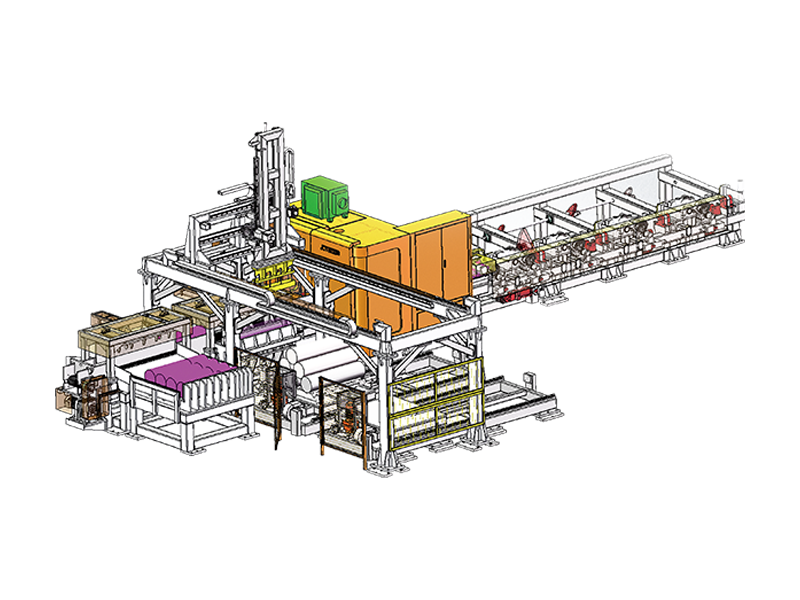

An automatic saw machine is a machine tool used for cutting materials into specified shapes or sizes. Unlike traditional manual saws, these machines are powered by motors and are capable of performing tasks autonomously. They can be operated with the help of a computer or programmable logic controllers (PLCs), which allows for a wide range of cutting options and even complex cutting patterns.

These saws come in different varieties, such as circular saws, band saws, and miter saws, each designed to handle specific materials and cutting needs. The real difference lies in their ability to operate autonomously with minimal human oversight, making them a powerful tool in various manufacturing settings.

Advantages of Using Automatic Saw Machines

Faster Turnaround Times

When you need to keep production moving at a high speed, manual cutting methods often can't keep up with demand. Automatic saw machines provide rapid cutting cycles, enabling manufacturers to process large quantities of materials in a short amount of time. As they require minimal human intervention, these machines can operate continuously, ensuring fast and consistent output.

Improved Consistency and Accuracy

Manual cutting can introduce variability due to human factors, like uneven pressure or inconsistent angles. Automatic saw machines are built with sophisticated algorithms that ensure every cut is made precisely according to the specifications. This high degree of accuracy is especially important in industries like aerospace and automotive, where even a minor error can lead to costly failures.

Reduced Material Waste

When cutting materials manually, it’s easy to miscalculate measurements or misjudge the quality of cuts, leading to excess waste. Automatic saw machines can be programmed to optimize the cutting process, minimizing material wastage. This not only saves money but also contributes to sustainability by reducing the need for raw materials.

Enhanced Flexibility and Customization

Modern automatic saw machines come with the ability to program various cutting patterns and shapes. This flexibility allows manufacturers to tailor cuts to specific needs, whether it’s creating intricate designs or adjusting for varying material thicknesses. As industries continue to demand more custom products, the ability to quickly adjust settings on an automatic saw machine is a significant advantage.

Improved Worker Safety

Safety is a top priority in any manufacturing environment. Automatic saw machines come with safety mechanisms, such as automatic shut-offs and enclosed cutting areas, that protect workers from potential harm. By removing the need for workers to be in close proximity to the cutting blades, these machines significantly reduce the risk of accidents.

Reduced Maintenance and Downtime

Automatic saw machines are built to last, with high-quality components that require minimal maintenance. Furthermore, many models come with diagnostic systems that alert operators to any potential issues before they lead to machine failure. This reduces downtime, ensuring that production schedules are not disrupted due to unexpected machine malfunctions.

Where Are Automatic Saw Machines Used?

Automatic saw machines find applications across various industries, including:

Construction: Cutting metal beams, pipes, and other structural components to precise lengths.

Furniture Manufacturing: Cutting wood and composite materials into panels for cabinets, tables, and other furniture items.

Automotive: Cutting metal parts for vehicle assembly lines.

Packaging: Cutting cardboard, plastic, or other materials for boxes and containers.

中文简体

中文简体 русский

русский